What Are Sapphire Windows Used For?

We manufacture high quality, precise components and assemblies.

Overview

Sapphire windows play an integral role in industrial, military, and medical fields. Do you know how many different uses these parts have in the world around you?

At Analytical Components, our team specializes in providing superior components for precision engineering and manufacturing. Sapphire windows are part of what we provide with the highest level of quality possible.

Just How Strong Are Sapphire Windows?

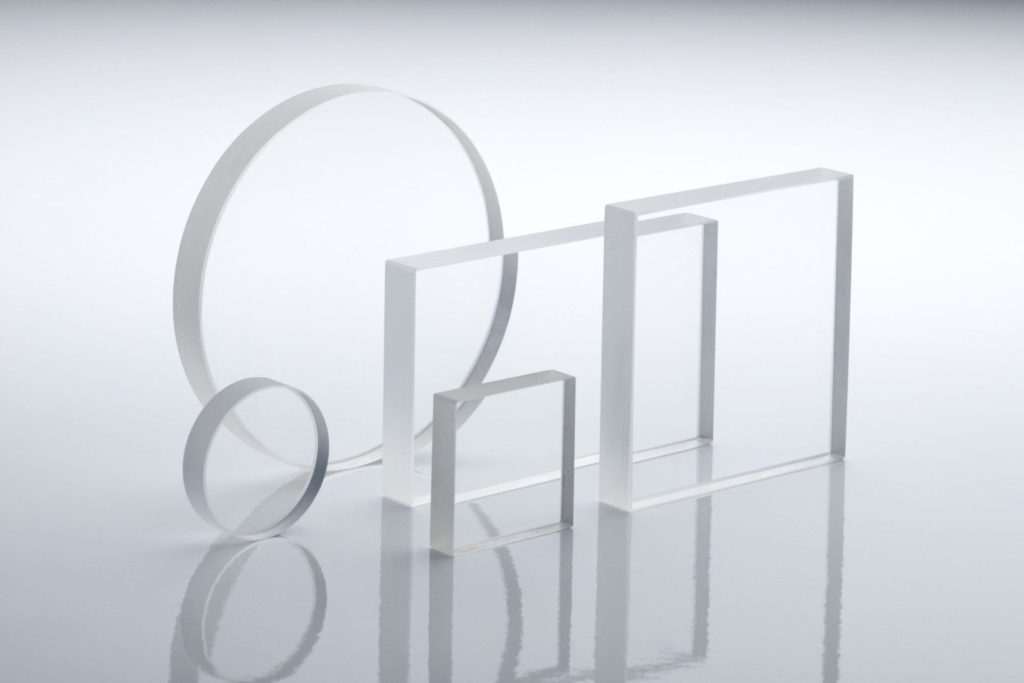

As a raw material, sapphire is the second hardest mineral next to diamond, allowing it to be shaped and cut easier for industrial uses, while still providing incredible benefits of strength and scratch resistance.

Sapphire windows are incredibly strong, even in their thin, layered form. These windows are clear, yet able to withstand a variety of caustic chemicals in high pressure, extreme-temperature environments.

These windows can withstand compressive pressure ten times better than stainless steel, all while providing varying levels of clarity based on the grade.

Different grades are often not an indicator of quality, but industry purpose. Depending on the needs of the industry, sapphire windows may be produced at different specifications.

For example, optical windows must be made to resist scratching and maintain complete clarity even in microscopic conditions.

Optical windows in manufacturing, however, do not need to maintain perfect optical quality, allowing more focus placed on its temperature, pressure, and chemical resistance.

What Are Sapphire Windows Used For?

Sapphire windows are ideal for many industrial applications, renowned for their structural integrity in high pressure and extreme temperature environments. (1)

Because of its ability to remain chemically inert, the ease of sanitization, and resilience to scratches and fractures, sapphire windows have also been used in a wide variety of military and medical uses.

Several common uses of sapphire windows include:

– Endoscopic instruments

– Military-grade lasers

– Submarine glass

– Furnace viewports

– Aerospace windows

– Barcode readers

– Gunsights

– Drilling vision systems

– Microscope lenses and slides

“Apple uses sapphire glass for the protective covers of its camera units, as well as the home button on its latest iPhone.”

- Matthew Panzarino

In recent years, the material is also being used much more widely in less rigorous but otherwise fragile applications, such as cell phones, camera lenses, and other areas of consumer technology.

It is expected that with a need for more sapphire windows and new manufacturing processes to decrease the production costs, this glass will become less expensive to create and more available to the public, replacing other forms of tempered glass as production costs lower.

Cell phones, camera lenses, microscopes, and computers are expected to be the first pieces of personal technology for this to be tested on. As production costs lower, more technology is expected to follow suit in replacing the silica-based glass.

Why Are Sapphire Windows Such High Performers?

Sapphire windows are known as being high performers in any industry for their overall versatility and ability to withstand abrasive applications that would otherwise break glass made of silica.

These windows are popular because of its unique ability to withstand such extreme conditions yet provide precise optical clarity in almost any application.

The base sapphire crystals are grown in a lab, allowing Analytical Components to shape its form as needed for the individual application before grinding and polishing the final product. This lab-grown method is just as strong as raw sapphire but significantly reduces the cost to supply parts.

This material is wear-resistant, allowing it to be used for several years before it needs to be replaced, minimizing replacement and repair downtime for consumers.

Even when exposed to many caustic chemicals and abrasives like sand and other small particulates, sapphire windows show little wear, reserving the clarity of the glass.

Sapphire windows do not bend or warp when exposed to high pressure or extreme heat and cold, allowing them to be used in a variety of applications from submarine equipment to cryogenics and molten metal containment.

Analytical Components: Your Source for Quality Sapphire Windows

The team at Analytical Components has been in the precision component engineering and manufacturing business for over 50 years, serving customers with the highest standard of quality possible.

Need an expert quote for your next project, or want to discuss our other services? Contact us today.

RECEIVE A QUOTE

- Matthew Panzarino, Apple Expands ‘Made in USA’ Efforts with Sapphire Glass Plant,

https://techcrunch.com/2013/11/04/apple-confirms-its-expanding-its-domestic-manufacturing-initiative-with-sapphire-glass-plant-in-arizona/