Synthetic Sapphire in High Pressure and Extreme Applications

If you want to learn more, you’re in the right place.

Let's discuss usage in high pressure and extreme applications

Overview

This paper explains the capability of synthetic sapphire in high pressure and extreme applications. Additionally, we will explore the manufacturing and assembly orientation utilizing synthetic sapphire material, and touch on defects that can adversely affect material performance in applications that use sapphire as sealing surfaces. Typical uses for these components require deliberate design choices and tightly toleranced assemblies for fail safe applications.

Synthetic sapphire, a single crystal form of aluminum oxide, has gained significant attention and application in various industries due to its exceptional properties, including high strength, hardness, transparency, and chemical resistance. This paper explores the use of synthetic sapphire in high pressure and deep-sea applications, highlighting its unique features and advantages in these extreme environments. We discuss the manufacturing process of synthetic sapphire, its key properties, and the specific applications in high-pressure and deep-sea scenarios. Furthermore, challenges and potential future developments in the field are also addressed.

Understanding Synthetic Sapphire

Advancements in technology have led to the exploration of extreme environments, such as high-pressure and deep-sea environments. These environments pose numerous challenges, including extreme pressures, corrosive substances, and low temperatures. Synthetic sapphire has emerged as a material of choice for these applications due to its remarkable properties and resilience. This paper aims to provide an overview of synthetic sapphire’s utilization in high-pressure and deep-sea applications, highlighting its characteristics that make it suitable for such demanding conditions.

Synthetic sapphire is a robust, versatile material that can withstand harsh conditions and is suitable for a wide variety of applications. Since synthetic sapphire is an aluminum oxide material grown in hexagonal crystalline form, it is hard and has a high resistance to heat and extreme chemistries. Due to its crystalline structure, material and optical characteristics can change depending on the orientation of the crystallographic planes to the designer’s placement. The material can be milled, drilled, cut, lapped, and polished into many sizes, shapes, and surface finishes while maintaining lattice orientation thorough out the material processing stages. These finished pieces can be used in aggressive environments where reliability, optical transmission properties and hardness are required.

How Synthetic Sapphire Could Have Helped the OceanGate Submarine

The recent tragedy of the OceanGate submarine that vanished during an attempted dive to the Titanic wreckage has raised questions about the safety of deep-sea exploration. One potential design flaw that has been discussed is the use of an acrylic window as the viewing window. Acrylic is a strong material, but it is not as strong as synthetic sapphire.

Synthetic sapphire is a transparent, high-strength material that is often used in applications where extreme durability is required. It is more resistant to scratching and cracking than acrylic, and it can withstand much higher pressures.

If the OceanGate submarine had been equipped with a synthetic sapphire window, it is possible that the accident could have been avoided. The synthetic sapphire window would have been more resistant to the pressure of the deep ocean, and it would have been less likely to crack or shatter.

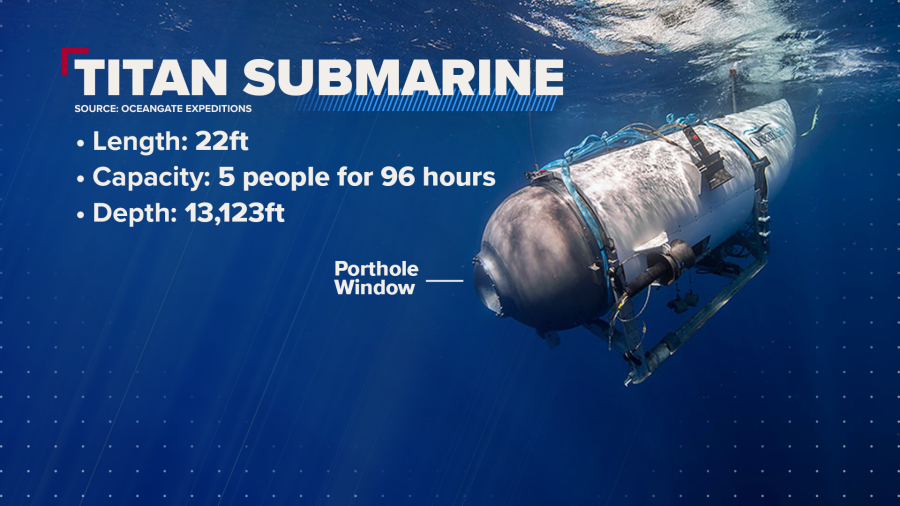

At Analytical Components LLC, we have worked with customers to develop synthetic sapphire viewing windows that can be used in deep sea applications. We have performed finite element analysis to model sapphire window usage at ~4.25 miles below sea level (22,440 feet). In comparison, the Titanic wreckage that OceanGate was attempting to reach is ~2.4 miles below sea level (12,672 feet). See image #1 for some of the Titan submarine details.

Manufacturing Process

Synthetic sapphire is produced using various methods, including the Verneuil process, the Czochralski method, and the heat exchanger method. These methods involve the growth of sapphire crystals in a controlled environment, resulting in high-purity and structurally robust materials. Synthetic sapphire possesses several properties that make it ideal for high-pressure and deep-sea applications. These properties include exceptional hardness (second only to diamond), high transparency in the visible and near-infrared spectrum, excellent chemical resistance, high melting point, low thermal expansion, and remarkable strength. Furthermore, synthetic sapphire exhibits minimal birefringence and is an electrical insulator.

High Pressure and Deep Sea applications

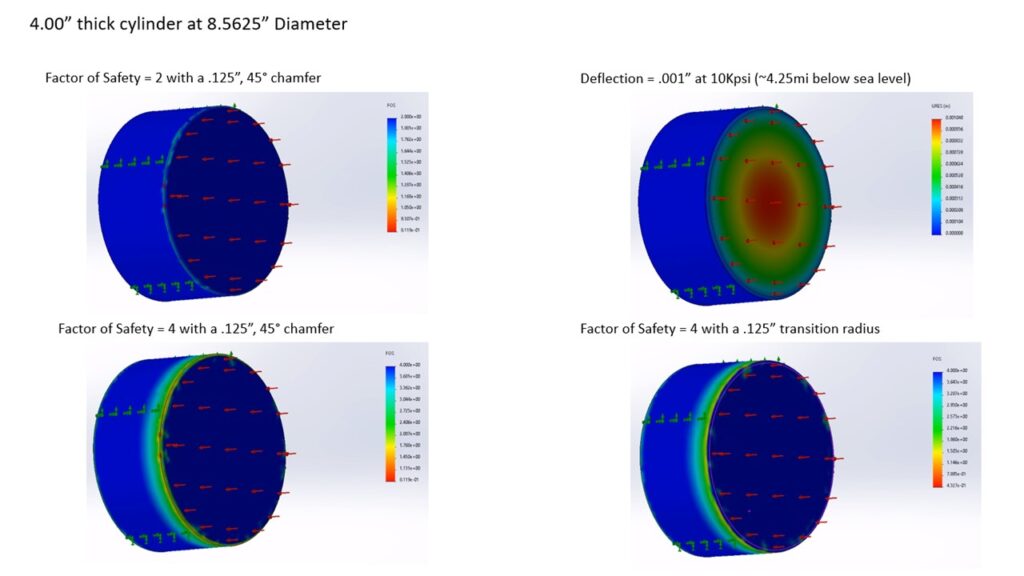

Synthetic sapphire is widely used as windows in high-pressure chambers and equipment. Its high transparency allows for the transmission of light or laser beams without significant attenuation, enabling observation and experimentation under extreme conditions. Synthetic sapphire’s excellent transparency and resistance to high hydrostatic pressures make it an ideal material for windows in submersibles and remotely operated vehicles (ROVs). These windows allow for clear vision and optical instrumentation at great depths, ensuring the safety and efficiency of underwater exploration. The exceptional optical properties of synthetic sapphire, combined with its resistance to corrosion from saltwater, make it suitable for the construction of lenses, prisms, and other optical components used in deep-sea exploration. Synthetic sapphire lenses offer superior clarity and durability, enabling high-quality imaging in challenging underwater conditions. Finite Element Analysis (FEA) modeling synthetic sapphire for a customer deep sea application (~4.25 miles below sea level) show sapphire to be a an extremely robust option as a viewing window in an ROV. See image #2 where locations of stress can be evaluated visually using factor of safety (FOS) scaling. Design optimization is more predictable due to the uniform structure of raw material sapphire; features and material defects that can reduce expected performance should be understood and minimized during the sapphire component design and production process.

Image #2

Conclusion / Summary

The remarkable properties of synthetic sapphire, including its exceptional mechanical strength, chemical inertness, optical transparency, thermal stability, and resistance to corrosion and abrasion, make it an ideal material for high pressure and deep sea applications. Its deployment in pressure windows, underwater optics, submersible vehicles and sensors, deep sea exploration and research, and the oil and gas industry has proven its effectiveness.