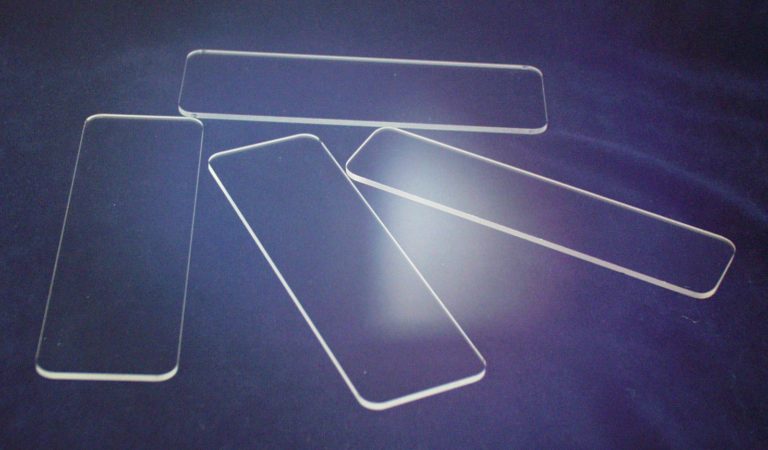

Custom Sapphire Windows

We manufacture high quality, precise components and assemblies.

Features of Our Sapphire Windows

Custom sapphire windows provide a mixture of strength and optical clarity; qualities that have clearly revolutionized precision manufacturing. Downtimes are significantly decreased as the parts last longer and handling dangerous chemicals in the lab and in production lines becomes safer.

Depending on the intended use, sapphire windows may be created in a different diameter, with a distinct coating applied. This can change which properties are highlighted in the final product.

Analytical Components is a sapphire window manufacturer and an industry leader in providing precision manufacturing equipment with OEM specifications in mind. To get your custom part, contact one of our specialists today.

A Scratch Resistant Window

Scratch resistance is a necessary part of many manufacturing uses where the user must be able to see through the lens reliably, or where abrasive materials wear down on the lenses frequently. The need for this property is common in medical, military, and consumer industries.

The importance of scratch resistant sapphire windows in these industries share a need for pure, transparent materials with a minimal arc, whether the use is imbuing military-grade automobile windshields with further battle protection, to cover DSLR cameras and render a better image, or in medical tubing to protect internal cameras.

Because it is often difficult and time-consuming to replace these lenses or other parts in the manufacturing process, the strength of a sapphire lens provides up-front and clear value as it can reduce the maintenance downtime for repairs. On average, sapphire glass lasts longer than the parts they replace of a different material.

Temperature and Chemical Resistance

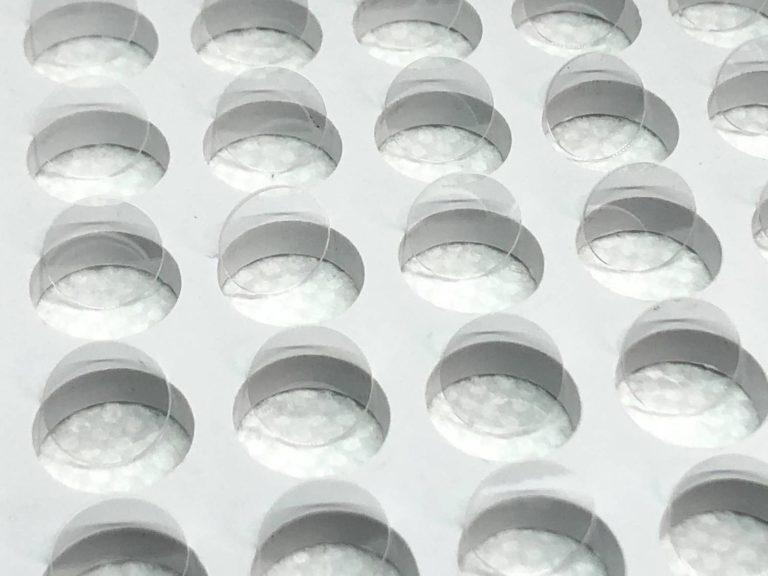

Sapphire may be crafted into a variety of shapes such as lenses, windows, or rods. These windows are valuable in uses that require temperature and chemical resistance.

These windows can support a temperature as high as 1950°C without any change to its shape or physical properties.

Because of this superior resistance, sapphire windows and rods are often utilized in high heat applications such as furnaces and the movement of molten metal. This allows manufacturers the optical benefits similar to a fused silica lens with durability greater than steel with less protective coating for the material.

Furthermore, sapphire windows and lenses are resistant to high frequency chemical exposure, even in corrosive or abrasive applications. The sapphire windows resist chemical etching, providing a longer-lasting product under high stress than fused silica glass or steel.

RECEIVE A QUOTE

Sapphire Optics: Better Than Glass

Optical components that can withstand harsh conditions are widely sought after, particularly as the material becomes more economical through cost-effective production and demand.

The properties that render sapphire windows better than glass – with less production downtime and fewer repairs – are incentivizing many manufacturers to make the switch to the harder windows.

Fused silica, while translucent, doesn’t have the fine degree of purity required by optical glass. The properties of sapphire, in addition to optical coating, to further enhance the lens clarity, make the ideal custom sapphire product in both optical glass and intense manufacturing uses.

When creating sapphire windows for optics, the transmission of light must be kept in mind. The sapphire windows’ or lens’ curvature must be minimal to retain the optical purity, though this can change dramatically with the design.

Custom Sapphire Windows Are Ideal for Demanding Applications

While custom sapphire offers a high level of translucency, making windows the right choice for optical applications, sapphire can also be used for other applications in manufacturing products.

Able to withstand far more pressure, abrasion, and contact with chemicals than standard glass, Sapphire is becoming a popular choice for many industries from military gear to medical equipment, and common cameras. (1)

“It is very hard. On the Mohs scale of mineral hardness, corundum is a 9 and the scale runs from 1 to 10. 1 is talc […] corundum is 9 and diamond is hardest at 10”

- Forbes.com

This mineral, a type of corundum, is becoming less expensive to produce as production expands, widening the applications it may be used for. Production cost can range depending on the size and diameter of the component, though different products require different part specifications.

Sapphire Windows: Ideal for Manufacturing and Optical Applications

When working with sapphire windows, the grade is use-dependent. For example, optical impurity in a window isn’t a concern when the sapphire is used in hot or high-pressure environments.

Optical purity is critical, however, when used in applications that require the production of precise prisms, or lenses that are resistant to abrasive materials. Each lens must have a clear aperture percentage of 90% or greater to be considered an optical lens.

Different coatings may be applied to provide optical filters, further scratch resistance, or chemical resistance to make it better suited as optical glass.

Lenses, Windows, and Rods Available in OEM Specifications

The experts at Analytical Components have direct experience with original equipment manufacturer (OEM) specifications, allowing us to create components that match your exact project needs, no matter the equipment you are purchasing it for.

Each component is created with the purpose in mind, ensuring the part is compatible with other components in your machinery. Our goal is to provide you with quality precision manufacturing equipment that gets the job done right with minimal wear on the machine and lower the mean time between mechanical failure.

Work with us to custom-tailor your windows to the exact specifications that your use requires, and our team will produce the part for you.

Custom Sapphire Shapes Available

Analytical Components is your top resource for acquiring sapphire custom manufacturing components. With over 50 years of experience in the precision manufacturing industry, our experts are dedicated to providing you with the highest quality for a fair price.

Our in-house process allows us to precisely calibrate, shape, and polish the sapphire so that it matches virtually any OEM requirement for your use. Each piece is laser cut for precision quality like glass, allowing the window or lens to be used for a variety of applications.

Each batch of sapphire goes through rigorous quality control testing to ensure it retains the same desirable properties that you come to expect from premium-quality sapphire windows.

Ready to Talk to a Specialist?

To place an order, get in touch with one of our experts to discuss your project and the type of products your company produces. At Analytical Components, we work with you to custom-tailor each part to the specifications your machinery requires, whether it’s optical components, rectangular sapphire windows, ball lenses, prisms, or sapphire glass windows for caustic protection.

Depending on your needs, our sapphire stock is available to ship right away, or our certified specialists can grind and polish windows, rods, and lenses into the desired custom shapes.

Learn more about our services or start a project consultation session today by phone or email. Based on your project requirements, we’ll provide you with a quote and next steps for getting your bespoke sapphire windows, lenses, rods, or other components in on time to help you meet company quotas.

RECEIVE A QUOTE

1. Forbes.com, iPhone 6 Sapphire Display: Everything You Need to Know, https://www.forbes.com/sites/gordonkelly/2014/07/25/iphone-6-sapphire-display-everything-you-need-to-know/?sh=739ba3797d3e