Large Sapphire Windows Suppliers │Big Size Sapphire Windows

We manufacture high quality, precise components and assemblies.

Sapphire windows have become a reliable and popular choice in various products. One might wonder why a manufacturer would want to jump on this bandwagon of a natural material switch and why many companies, economic sectors, and industries use sapphire instead of the other materials used in glass production.

The versatility of sapphire has made it possible to create windows of various shapes and sizes. The manufacturers and suppliers of these windows understand this and produce large sapphire windows or small ones according to the needs of consumers. However, before talking about supplies or sizes of sapphire windows, it is expedient to consider what makes sapphire so valuable to the manufacturers that use it as a raw material in their production processes.

From Smallest to Largest Sapphire Windows

The uses of sapphire windows range from small scale to large scale. As some manufacturers need them small according to the size of their end component, large ones are also required for those that want to achieve a larger end component. So, manufacturers ensure that their products are custom-made to meet specific needs in terms of size and every other pertinent property.

The sapphire windows are grouped according to size, shape, or nature.

Sapphire Step Windows

Sapphire step windows, also referred to as T-windows, are perfect for vehicles that navigate the ocean’s depths. Since the windows of such cars are made of sapphire, they can easily withstand all the pressure exerted by saltwater and debris in the deep.

Wedged Sapphire Windows

Wedged sapphire windows are made to provide an additional layer of transmission and strength when eradicating the occurrence of fringe patterns and cavity feedback. They can shield components from the delicateness of the laser while ensuring that the beam isn’t compromised.

Rectangular Sapphire Windows

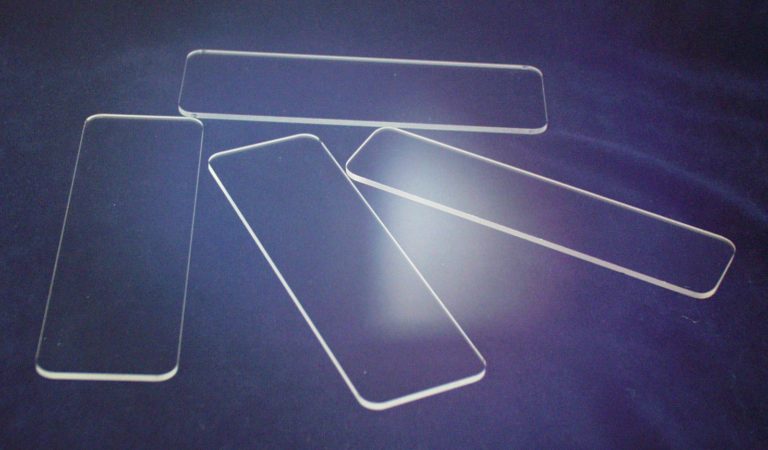

Rectangular sapphire windows and other various shapes of sapphire glass are called custom-shaped sapphire windows. From the smallest ones to the largest, they are made to safeguard delicate optics, and they can attain a flatter shape than the other optical windows.

Large Diameter Sapphire Windows

The term “diameter” indicates that these types of windows are circular. These large-diameter sapphire windows are used in research and defence, and their large optics shield lasers and bigger infrared cameras from scratches.

Wholesale large sapphire windows

If you wish to purchase large sapphire windows at wholesale for large orders, contact our team today to get the best quote for your situation.

RECEIVE A QUOTE

Ultra-thin Sapphire Windows

As the name implies, this sapphire optical window is processed so that it has a very thin dimension; usually about 100 microns. They have excellent compatibility with products that require flatness for their surface finish. Their narrow optical property is helpful for lighting purposes. They are used in most semiconductors, medical equipment, and electronic appliances.

Why Companies Opt for Small or Large Sapphire Windows

Although it has some counterparts, such as silica and quartz, sapphire has proven the most reliable and durable. Every manufacturer wants to produce something for their consumers that’ll stand the test of time and can weather the storms of circumstances, manhandling, or accidents while maintaining a quality that isn’t defaced. This is what sapphire offers.

Sapphire windows are glass substances that are clear and crystalline. They are made from sapphire, a rigid material that is grown synthetically. Even though they look a lot like conventional glasses initially, they are much more substantial. They can withstand significant amounts of pressure and extremely high and low-temperature levels.

The hardness of sapphire has been related to that of a diamond. Next to diamond, it is considered the second hardest mineral in existence. However, its durability and strong resistance to scratches might just be second to none. Despite this incredible strength, it is easier to cut it into various shapes or sizes according to varying industrial specifications. The shape, size, or thickness does not translate to quality that is watered down; the strength is maintained no matter how it is shaped in line with the desired result.

Properties of Sapphire in Glass Production

What are those specific properties of sapphire that make it so desirable? Why does it seem like it has virtually all that manufacturers need to achieve incredible durability in their products? Here are some properties that explain why it is highly sought after, even though it can be expensive:

Chemical Inertia

The crystal structure of sapphire makes it so stable that it doesn’t respond to the condition of its immediate environment. Therefore, it can withstand various chemical conditions and come out without damage or defacement, no matter how harsh those conditions may be.

Optical Property: Transmission of Light Without Impedance

Its high refractive index allows for a wide transmission spectrum covering the ultraviolet, visible, and infrared. This property is beneficial in optical applications, as light can now be easily transmitted through optical windows without the impedance constituted by scattering or any other related phenomenon.

Extreme Hardness and High Scratch Resistance

Sapphire is one of the most complex, most robust, and most durable materials in existence. This is why it perfectly fits the production settings that require durability and strength to achieve production goals. Its high resistance to scratches also makes it very easy to sanitize.

Versatility and Temperature Resistance

You can mold sapphire into any shape or thickness that manufacturers want their products to assume without losing an ounce of its strength and durability. It also has the unique capacity to survive in extremely cold or hot conditions. Its cryogenic property has exceeded that of copper, and it also has a melting point that exceeds 2000ᐤC. This enables it to come out of extremely high or low temperatures unscathed.

General Applications of Sapphire

- Sapphire is used widely for commercial purposes. These can range from producing furnaces and ovens to manufacturing windows used in commercial aeroplanes. Furnaces need to be made with materials that can withstand the high temperature that it is usually subjected to; hence the use of sapphire in its production to avoid the risk involved if the raw material used is not strong enough. An aeroplane has to employ strong enough material to produce its windows since it has to be airtight while it is in the sky. Sapphire is perfect for this air pressure. The risk of scratches on the windows or breakage of the glass is also eliminated.

- It is used in semiconductors since the manufacturing process usually requires a certain level of ruggedness. The chemicals used in the production of semiconductors can quickly wear out materials such as ceramics or quartz. Therefore, sapphire is used to produce components, such as windows, tubes, rods, and other parts in machines necessary for manufacturing semiconductors. It survives the aggressiveness involved in the production and lasts long, unlike quartz and other counterparts.

- Medicine often incorporates optical windows in the production of laboratory tools and equipment. Its durability, resistance to scratches, and optical properties are essential to the medical industry.

- The military is also one of the most significant users of sapphire’s strength and optics. From surveillance equipment to protection from combat impact through the production of windows for air and ground vehicles, sapphire is valuable for various purposes in the army.

- It can also be found even in the mundane. Also, Some smartphone screens are now protected by sapphire. It can also be used for producing the lens of some eyeglasses. Some luxury wristwatches also use it.

KY Sapphire Growth

The sapphire used in the production of windows is a material grown synthetically in laboratories. Sapphire is a rare mineral. Therefore, in the 1920s, The soviets devised a method to multiply the available amount. This method is referred to as the Kyropoulos method (usually shortened to KY). It involves immersing a seed crystal into fused material and then pulling it up at a specific rate and regulated temperature to produce a large single crystal that takes the semblance of a cylinder.

This method is still in use today by various producers to maintain the face of an optical product. Even though sapphire is a scarce mineral, this is how manufacturers of optical windows always manage to get enough raw materials to keep the industry afloat for years to come.

Why Analytical Components is the Best Choice for First-rate Sapphire Windows

At Analytical Components LLC, we are very particular about precision in our production process. We are passionate about precision component engineering. We take this passion and couple it with over fifty years of experience to continually manufacture products of unrivaled quality for the life science industry, semiconductor industry, and general industrial use.

Look no more if you’re in search of the best supply of sapphire optical windows. Whether small or big, we can bring your ideas to life through designs that are fashioned to meet your needs. Also, you need not worry about how compatible our designs will be with the components in your system that determine smooth running. Our direct experience with original equipment manufacturer (OEM) requirements and knowledge of the complex materials industry ensure that our products meet the necessary standards.

Order Today

You can place your order now by using the Receive A Quote form or one of the contact options available. Also, you can get more information regarding our products and services through these means. A correspondent from our team will get back to you as soon as possible and help you understand our production process so we can make your window precisely according to your needs.